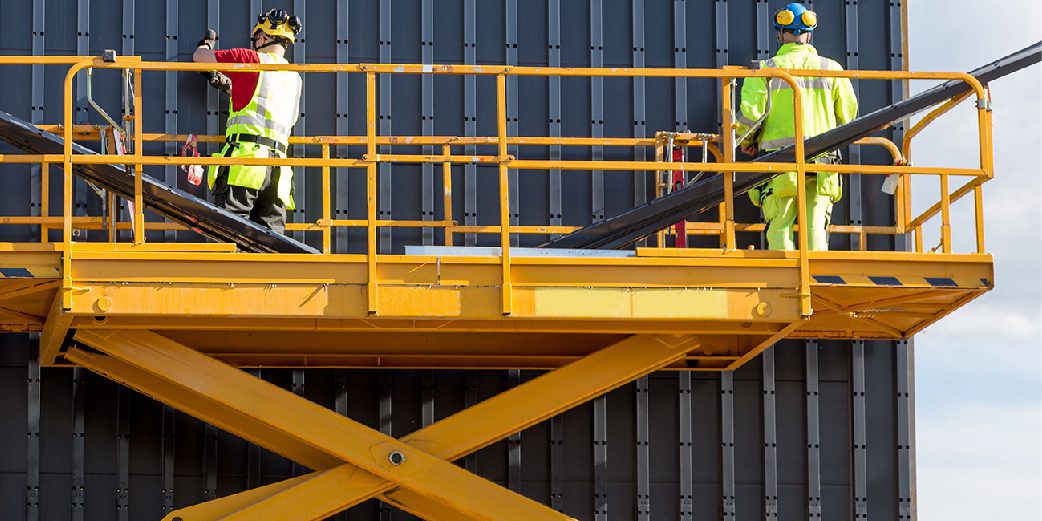

LOLER & PUWER Inspections

What is a Thorough Examination?

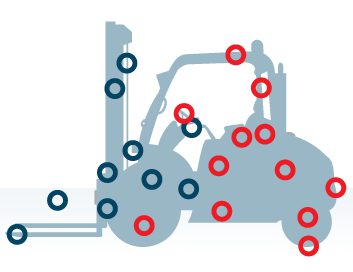

LOLER Inspection = Blue

PUWER Inspection = Red

LOLER & PUWER Inspections

A Thorough Examination, mandated by the Lifting Operations and Lifting Equipment Regulations (LOLER) and the Provision and Use of Work Equipment Regulations (PUWER), serves as a statutory requirement for lifting equipment. This examination is akin to a car MOT, providing a comprehensive report on the safety and usability of the equipment. It is important to note that a Thorough Examination differs significantly from routine maintenance inspections, with distinct responsibilities assigned to Competent Persons under the law.

The Role of Competent Persons

The legislation stipulates that a Competent Person, typically an experienced service engineer or examiner with a minimum of 5 years in the forklift industry, is responsible for conducting Thorough Examinations. At our organisation, all engineers undergo rigorous training and hold relevant licenses to ensure the highest standards of inspection. Regular revalidation training is conducted to uphold excellence and exceed industry norms.

Frequency of Thorough Examinations

According to legal requirements, all lifting equipment must undergo a Thorough Examination at least once a year. The frequency of examinations may vary based on factors such as equipment usage, work environment, and configuration. Equipment used for lifting people or equipped with additional attachments necessitates examinations every 6 months. If there are uncertainties regarding the examination schedule for your equipment, our team is readily available to provide guidance and support.

Examination Schemes for Enhanced Safety

An examination scheme outlines a detailed inspection checklist tailored to specific lifting equipment’s operational conditions. This scheme aids in aligning resources with risk levels effectively. Users, owners, manufacturers, or independent parties can develop examination schemes to ensure thorough assessments that may deviate from standard periodic examination intervals.

Addressing Identified Defects

If a Thorough Examination uncovers defects that do not pose immediate safety risks, a Report of Thorough Examination will be issued, highlighting the identified issues and setting deadlines for rectification. It is the user’s responsibility to promptly address the identified defects within the stipulated timeframe. For defects deemed hazardous, the equipment must not be used until the issues are resolved. In cases where equipment is withdrawn due to safety concerns, reports are legally required to be submitted to the relevant authorities.

What we inspect

How it works

Arrange

Easily book, manage, and securely store your Thorough Examination inspection certificates through our custom-designed online portal.

Inspect

An engineer from our team will conduct a comprehensive inspection by LOLER and PUWER regulations to ensure the safety and compliance of your equipment.

Report

Following the completion of an inspection, a Thorough Examination report will be promptly issued. All docs, including the report, is available through our secure portal.

No Contract

You're not bound by a long-term contract with us. We're here to support your business whenever you need us.

Faults and what they mean

There are three levels of faults that may be identified during an examination: “Now” faults, “A” level faults, and “B” level faults. Each of these levels has its own set of criteria and recommended actions.

“Now” faults

Beacon and horn faults may be risk assessed by the examiner, depending on site conditions and the use of the equipment. However, it is important to address these faults as soon as possible to ensure the safety of those using the equipment

“A” Level faults

“B” Level faults

“C” Level faults

Criteria for issue of Certificate

It is mandatory to address and resolve all faults classified as “Now” and “A” Level. Subsequently, written notification (job sheet copy/email) must be forwarded to either us or the Thorough Examination company to facilitate the issuance of the Certificate.

It is important to note that these levels of faults are not exhaustive and may vary depending on the equipment and its intended use. It is always best to consult with a qualified examiner to determine the appropriate course of action for any identified faults.

In the case of an old forklift with faults, it is crucial to have a thorough examination done to identify any potential hazards. This will not only ensure the safety of those using the equipment but also help in maintaining the longevity of the forklift.

In addition to addressing any identified faults, it is also important to regularly inspect and maintain the equipment to prevent any potential hazards. This includes observations and comments on the general condition of the equipment and any recommendations for improvement. By staying on top of maintenance and addressing any faults promptly, you can ensure the safety and efficiency of your operation.

Explore Statutory Inspections Resources and tips

Why inspecting electric truck batteries is crucial

Electric trucks have become increasingly popular in recent years due to their efficiency and...

What to look for when buying a used forklift

What to Look for When Buying a Used Forklift: A Pre-Purchase Inspection Guide Are you in the...

Forklifts: How much can you legally lift?

When it comes to lifting equipment, it is important to understand the legal requirements and...

Who is responsible for maintaining a valid

Thorough Examination certificate?

In most cases, the responsibility falls on the employer or the person in charge of the equipment. This includes ensuring that the equipment is inspected by a competent person and that any necessary repairs or maintenance are carried out promptly. However, it is also the responsibility of the operator to report any defects or issues with the equipment to their employer or supervisor.

It is essential to note that the responsibility for Thorough Examinations may vary depending on the type of equipment and the industry it is used in. For example, in the construction industry, the responsibility may fall on the contractor or the person in charge of the site. Therefore, it is crucial to understand the specific regulations and guidelines for your industry to ensure compliance.

In conclusion, the responsibility for ensuring that work equipment has a valid Thorough Examination certificate ultimately falls on the employer or the person in charge of the equipment. However, it is also the responsibility of the operator to report any issues or defects with the equipment. By understanding and fulfilling these responsibilities, we can ensure the safety and efficiency of our work equipment

You are renting or leasing a truck long-term

(more than 12 months)

If you are renting equipment on a long term basis, you are responsible for making sure the truck has a valid Thorough Examination certificate.

You are the owner of the truck

If you, or your business, owns the truck you are wholly responsible for ensuring a valid certificate of Thorough Examination.

You are renting or leasing a truck for a short

period of time (up to 12 months)

If you are renting the equipment for up to a maximum of 12 months, then the company who owns equipment is responsible. Therefore you should ensure that you get a report and certificate of Thorough Examination when taking out the lease. This will keep you within HSE guidelines and will be needed for any auditing purposes.

Please get in touch, our team will be happy to help.

Experienced examiners

All our engineers are not only competent but also fully trained and licensed to carry out inspections on workplace transport. We prioritise continuous professional development through regular revalidation training to guarantee a high standard of work that consistently exceeds industry norms.

High Standards

Our unwavering commitment is to deliver a first-class service that offers excellent value for money. By investing in a team of highly skilled and experienced engineers, we ensure that inspections are completed with professionalism and efficiency. This approach is designed to minimise any disruption and downtime to your operations, allowing for seamless business continuity.

ISO 9001:2015

ISO 9001 is the internationally recognised Quality Management System (QMS) standard. Defining commitment to creating services in accordance with pre-defined standards.

UK MHA

The UK Material Handling Association (UKMHA) is a non-profit organisation representing all sectors of the UK material handling industry, committed to enhancing standards and providing audit, advisory, and training services

SafeContractor

SafeContractor is the UK's leading Health and Safety Accreditation, supporting you by helping to demonstrate a commitment to sustainable and ethical practices.

Thorough Examinations

A Thorough Examination is a mandatory inspection to ensure the safety of lift trucks by checking their mechanical parts, similar to a car MOT. Go digital, go green and protect the trees.